Innovations in 3D Printing

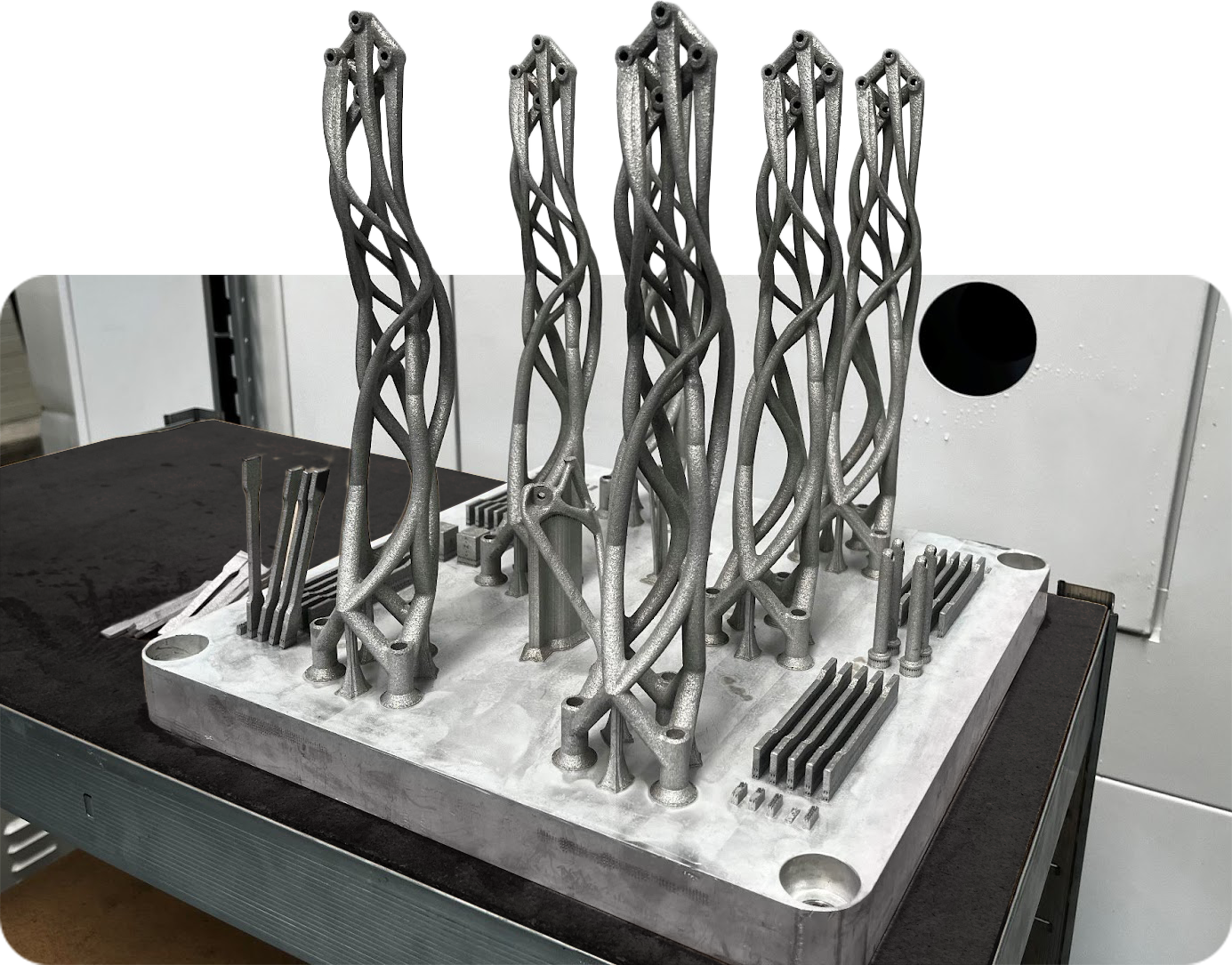

Increased design freedom with metal 3D printing

Metal 3D printing allows for the production of geometries that are difficult or even impossible to produce using other methods, which provides greater freedom in designing innovative solutions.

EOS M400

Specialised large-scale metal 3D printing machine

Materials

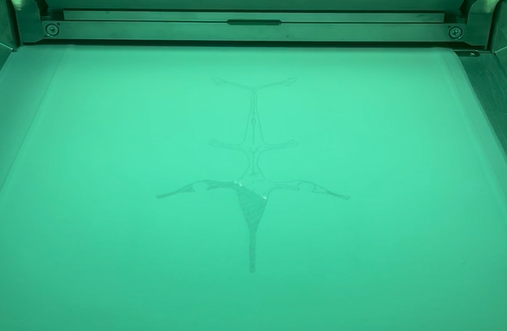

The use of high-strength materials

in 3D printing

The use of high-strength materials allows the application of printed elements in structures that carry heavy loads. The strength of printed parts is comparable to, and can even be higher than, those manufactured using traditional methods (e.g. casting, CNC), while reducing weight by up to 80%, thanks to volume optimization.

Available materials include:

► See all materials

Design Requirements

How to prepare a project for printing?

Characteristics

Maximum volume

400mm x 400mm x 400mm

Tolerances

Best tolerances - <100mm: ±0.2mm, <200mm: ±0.3mm, <300mm: ±0.4mm, 300-400mm: ±0.4-0.5mm

Layer height

Depends on the material

Aluminium AISi10Mg - 0,09mm

Surface finish

The raw print has a high roughness, which can be leveled by sandblasting or machining.

Printed elements may have coatings applied and may be subject to chemical processes, such as nickel plating.