Surface testing

Hardness test

The eHandy Esatest hardness tester from Ernst is a portable, wireless handheld device for measuring the hardness of metals even in hard-to-reach places like holes or pockets. It works on the principle of measuring electrical resistance, which is a function of the depth of the indenter (ERNST patent). This innovative technology does not destroy the surface, so the tested element remains without noticeable losses. The test can be carried out on any scale (i.e. HB, HV, HR and others) and takes only a few minutes.

Surface testing

Portable roughness measuring device

Waveline W10 from Jenoptik (Hommel-Etamic) is a new generation

of devices for fast and accurate control of roughness directly on the production line as well as in quality control laboratories. The device consists of a mobile measuring head and a parameter evaluation unit with a printer and a docking station. The test can be performed

on almost any surface including holes.

Surface testing

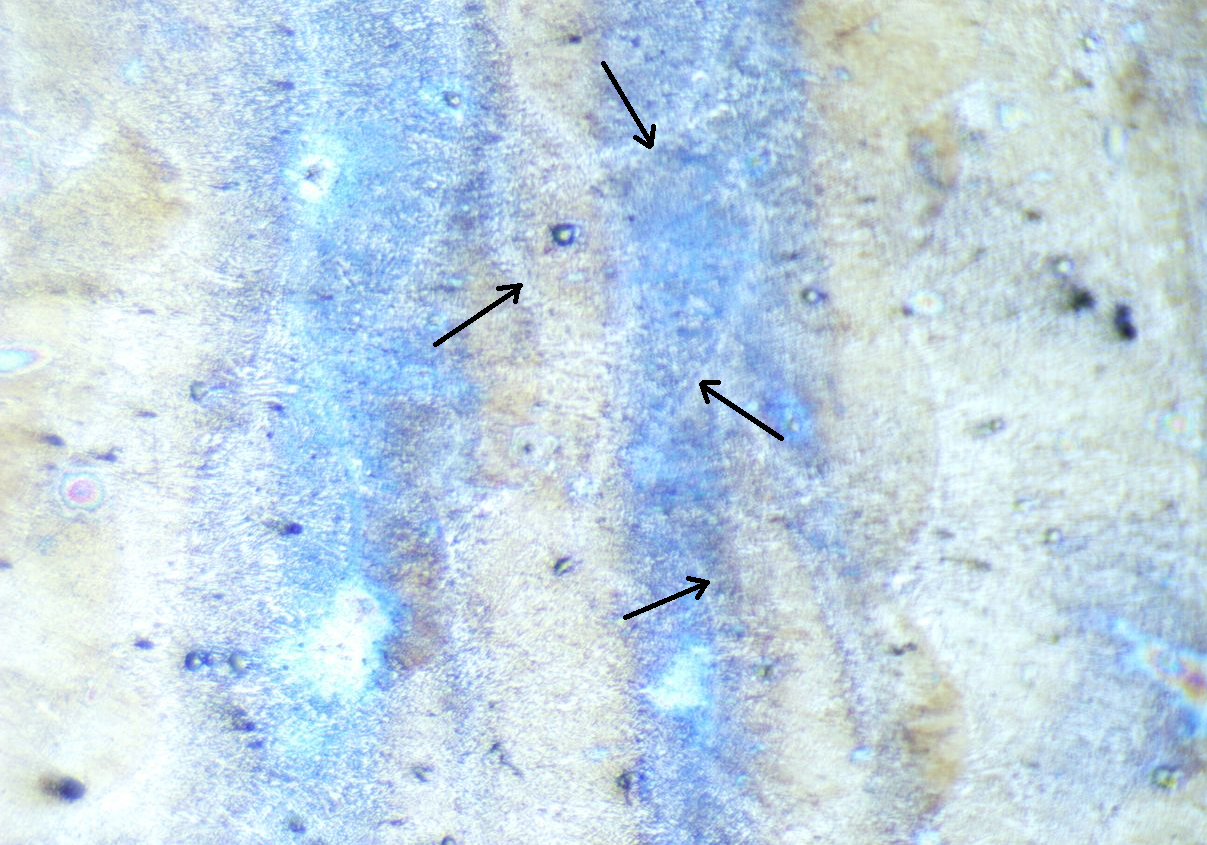

Metallurgical microscope

A specialized microscope that can perform visual analysis of surfaces. Thanks to the advanced camera and software, it is possible to record video, measure artifacts, take multi-layer 3D images and complex images of a large area.

Material composition testing

Optical emission spectrometer

GNR MiniLab 150 - enables elemental analysis of low-alloy steels, stainless steels, chromium, chromium-nickel, cast irons, free-cutting and tool steels, various aluminum alloys (including Al-Si, Al-Cu, Al-Si-Cu, low-alloy Al) and copper alloys (brass, bronze, low-alloy copper, aluminum bronze)