Innovative metal and polymer

3D printing services

As part of Hydropress, AMTH leverages breakthrough powder fusion technologies, advanced materials, and unparalleled design capabilities.

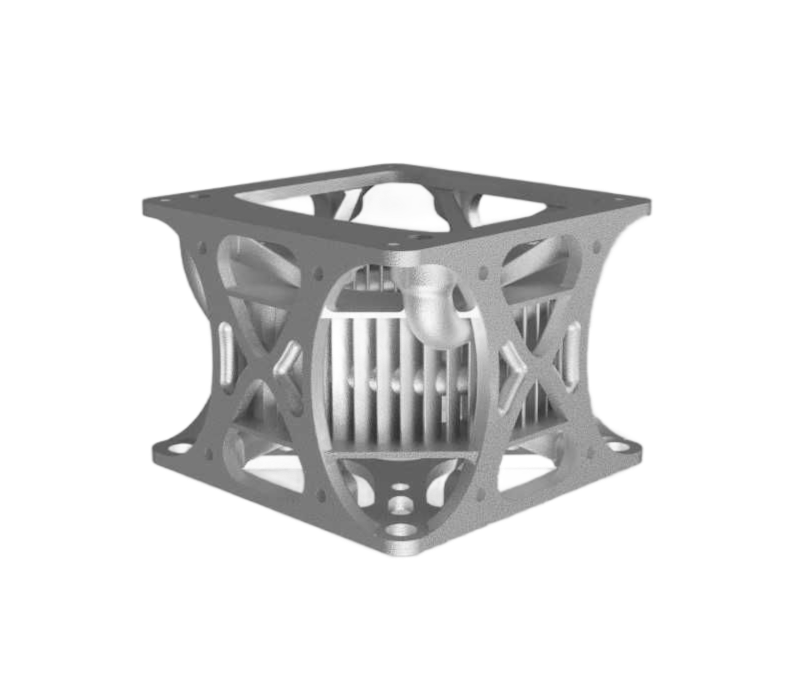

Direct Metal Laser Sintering

Metal 3D Printing

DMLS is an advanced powder-bed fusion technology that enables the production of complex geometries that would be difficult or impossible

to achieve with conventional methods. The comprehensive workflow from model preparation, through printing, to post-processing ensures precision, durability, and consistent quality of every component.

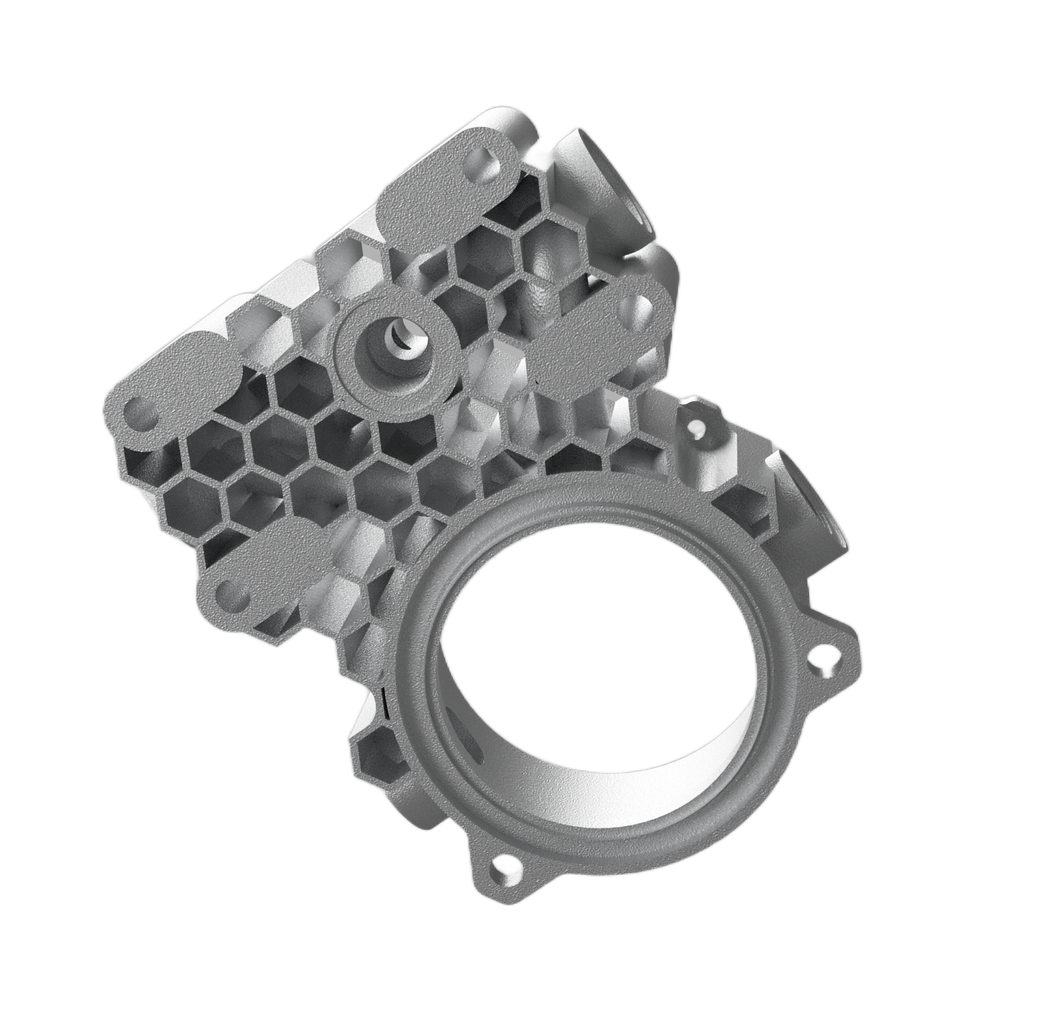

Selective Laser Sintering

Polymer 3D Printing

SLS is a modern technology of sintering polymer powders, allowing

for the production of complex components without the use of supports.

It combines high strength and dimensional accuracy with full design freedom, enabling the manufacturing of both functional prototypes

and finished end-use parts.

Discover the Possibilities

What are the benefits of metal 3D printing?

3D Printing Technology

Seven 3D printing technologies

There are seven main 3D printing technologies, which are based on various forms of input material, most often in the form of a wire, resin or powder, which is processed by heat, light curing or laser melting. Dynamically developing 3D printing technologies allow for the creation of products from almost any material: from various polymers and composites to durable metal alloys. At AMTH, we operate a modern machine park based on Powder Bed Fusion (PBF) technology, which enables the production of parts with the highest quality and precision.

bn

AM market value in $ by 2030

%

share of metals in global 3D printing material revenues

%

waste reduction achievable through additive manufacturing processes

%

of users plan to increase investments in 3D printing

Discover the Possibilities

Advantages of PBS over other AM methods

Industry Applications

See use cases

Stay up to date with the latest news!

We are excited to share the latest news from the world of 3D printing with you.

Sign up for our newsletter to be among the first to learn about our project's progress and research results.

Leave your email to:

- Receive regular updates on key milestones in the Hydropress project.

- Be informed about the opening of commercial orders.

- Have access to exclusive content and promotions.